GILSOFLEX ® by AMERICAN GILSONITE

For sustainable road construction in road construction and in areas with high traffic loads

Unique deformation stability and long service life.

Shorter road construction time and lower manufacturing costs.

BEST DEFORMATION STABILITY

AND UNIQUE ELASTICITY

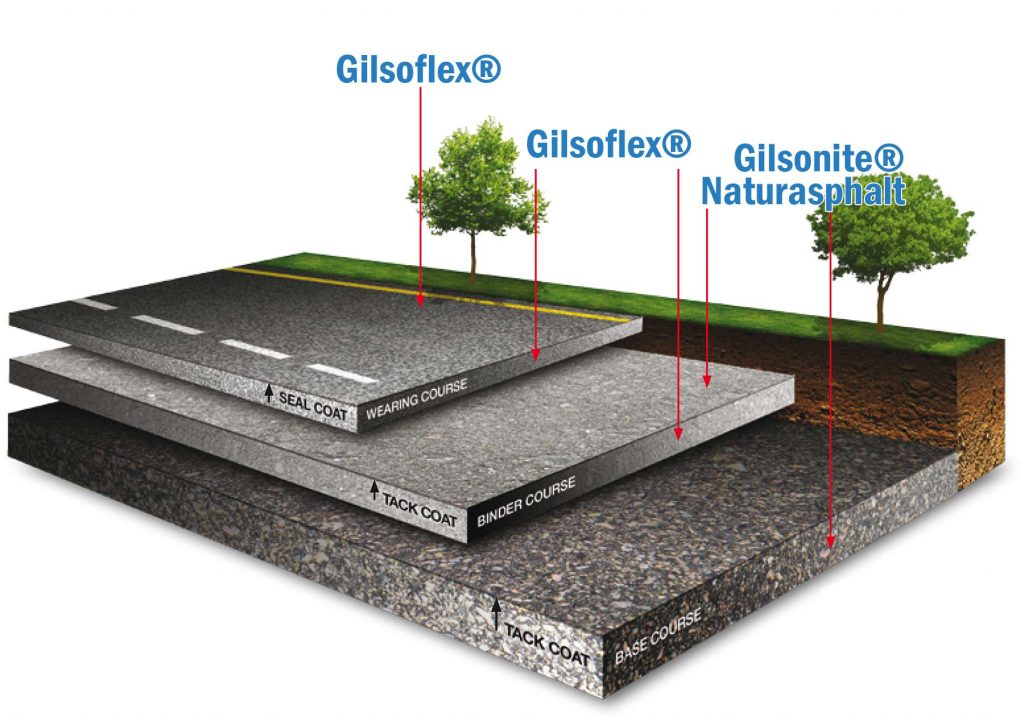

Gilsoflex combines the excellent deformation stability of Gilsonite with the elasticity and cold properties of a PmB and is primarily used in bituminous surface layers for heavily loaded asphalt structures such as roundabouts, congestion zones in front of busy intersections, bus bays or bus stops.

In conjunction with Gilsonite modified binder courses, a Gilsoflex modified surface layer offers unique deformation stability and service life with far less construction time and costs compared to concrete construction.

Gilsoflex is a granulate made from Gilsonite natural asphalt and an elastomer produced specifically for Gilsoflex.

Gilsoflex enables asphalt mixing plants to produce elastomer-modified bitumen in small quantities directly at the asphalt mixing plant.

Gilsoflex is a SIS modified natural asphalt that is used in road construction to modify hot asphalt mix.

Its use results in particular improvements in terms of stability, deformability, elasticity and the adhesion behavior of the bitumen to the rock.

Gilsoflex can be dissolved directly in hot bitumen and is produced in different mixing ratios as required.

It is available in various meltable PE bag packaging depending on your needs and can be added directly to the mixer.

Application Gilsoflex

Depending on the load, 5-20 M% of the 50/70 binder is replaced by Gilsonite/Gilsoflex. The addition is made either directly into the mixer or via the bitumen tank. To guarantee trouble-free compaction, the mix temperature during installation should be between 150 °C and 165 °C. All other parameters remain unchanged.

Experience has shown that traffic clearance can be granted earlier for Gilsonite/Gilsoflex modified pavements than is the case for unmodified asphalt pavements.

Packaging

Our natural asphalt additives are available in the following packaging sizes: